Introduction to Car Engines

A car engine is a vital component of an automobile, serving as the heart that propels the vehicle forward. Understanding how a car engine works is crucial for both car owners and enthusiasts, as it provides insights into the mechanics behind transportation. Essentially, the engine converts fuel into motion through a series of controlled explosions in a process known as internal combustion. This intricate process not only generates power but also regulates the vehicle’s overall performance, efficiency, and emissions.

There are several types of car engines, each differing in design and functionality. The most common are internal combustion engines (ICE), which can be further classified into petrol and diesel engines. Petrol engines usually operate on a spark-ignition system, where a spark plug ignites an air-fuel mixture, while diesel engines function on compression ignition, where fuel ignites due to high pressure within the cylinder. Alternatively, electric engines, which are becoming increasingly popular, utilize electric energy stored in batteries to power the vehicle, completely bypassing the combustion process.

The significance of a car engine extends beyond mere propulsion; it directly impacts fuel consumption, maintenance costs, and environmental considerations. With advancements in technology, many modern engines now incorporate turbocharging and hybrid systems to enhance power output while improving fuel efficiency. Additionally, understanding the difference between the various types of engines allows prospective buyers to make informed decisions tailored to their driving needs.

In summary, car engines play a fundamental role in automotive engineering, determining not only the performance but also the sustainability of vehicles. As automotive technology continues to evolve, a thorough comprehension of car engines becomes ever more relevant for consumers seeking effective and efficient vehicles.

Basic Components of a Car Engine

A car engine is a complex system composed of several critical components that work together to convert fuel into mechanical energy. Understanding these components helps in grasping how an engine operates. The primary elements include the cylinder, piston, crankshaft, camshaft, and valves.

The cylinder serves as the chamber where fuel and air mix and combust. Typically, an engine contains multiple cylinders arranged in a row or a V-configuration, which allows for smoother power delivery and higher efficiency. During the intake stroke, the air-fuel mixture is drawn into the cylinder, setting the stage for the combustion process.

Within the cylinder, the piston moves up and down, compressing the air-fuel mixture before ignition occurs. When the mixture ignites, the resulting explosion forces the piston downward, which translates to the rotation of the crankshaft. The piston’s design is crucial, as it must withstand high pressures and temperatures while maintaining a tight seal against the cylinder walls.

The crankshaft converts the linear motion of the piston into rotational motion. Positioned at the bottom of the engine, it is connected to the pistons through connecting rods. The continuous rotation of the crankshaft powers the vehicle’s transmission system, ultimately propelling the car forward. Its robust construction ensures durability and stability, essential for the engine’s performance.

Another significant component is the camshaft, which operates the valves. The camshaft is responsible for opening and closing the engine’s intake and exhaust valves at the appropriate times throughout the engine cycle. This synchronization is vital for efficient engine operation, as it ensures optimal airflow and exhaust expulsion.

Lastly, the valves are critical for regulating air and exhaust flow in the engine. There are typically two types: intake valves, which allow the air-fuel mixture into the cylinder, and exhaust valves, which let combustion gases escape. Their precise timing and operation are essential for the engine’s overall efficiency and performance.

The Internal Combustion Engine Cycle

The internal combustion engine operates primarily through a four-stroke combustion cycle, which comprises the intake, compression, power, and exhaust strokes. This cyclical process plays a vital role in converting fuel into mechanical energy that ultimately powers vehicles. Understanding each of these strokes is essential for comprehending how the engine generates power efficiently.

The cycle begins with the intake stroke, where the engine draws in a precise mixture of air and fuel through the open intake valve. As the piston descends in the cylinder, a vacuum is created, allowing this mixture to flow into the combustion chamber. This stage is critical as it ensures that a sufficient amount of the air-fuel mixture is available for the subsequent steps of the process.

Following the intake, the compression stroke takes over. During this phase, the piston moves upward, compressing the air-fuel mixture within the cylinder. The compression raises the temperature and pressure of the mixture, making it more conducive to ignition. This precise timing of compression is crucial for maximizing the efficiency of the combustion process, as a well-compressed mixture burns more completely when ignited.

The engine then enters the power stroke, where the spark plug ignites the compressed air-fuel mixture. This explosion pushes the piston down, generating the mechanical work that ultimately powers the vehicle. The efficiency of energy conversion during this phase is a significant aspect of internal combustion engine design, which aims to maximize power while minimizing waste.

Finally, the exhaust stroke occurs. After the power stroke, the exhaust valve opens, allowing the spent gases to exit the combustion chamber as the piston moves back up. This not only clears the cylinder for the next cycle but also ensures that the engine operates smoothly and efficiently. The entire process then repeats, showcasing the remarkable efficiency of the internal combustion engine cycle and its ability to convert fuel energy into useful work for powering vehicles.

The Role of Fuel and Air Mixture

The performance of a car engine is significantly influenced by the fuel and air mixture fed into it. This mixture must achieve an optimal ratio for the engine to operate efficiently, with a standard ratio often cited as approximately 14.7 parts air to 1 part fuel by weight. When this balance is disrupted, engine performance may suffer due to incomplete combustion, leading to reduced power output, increased emissions, and overall inefficiency.

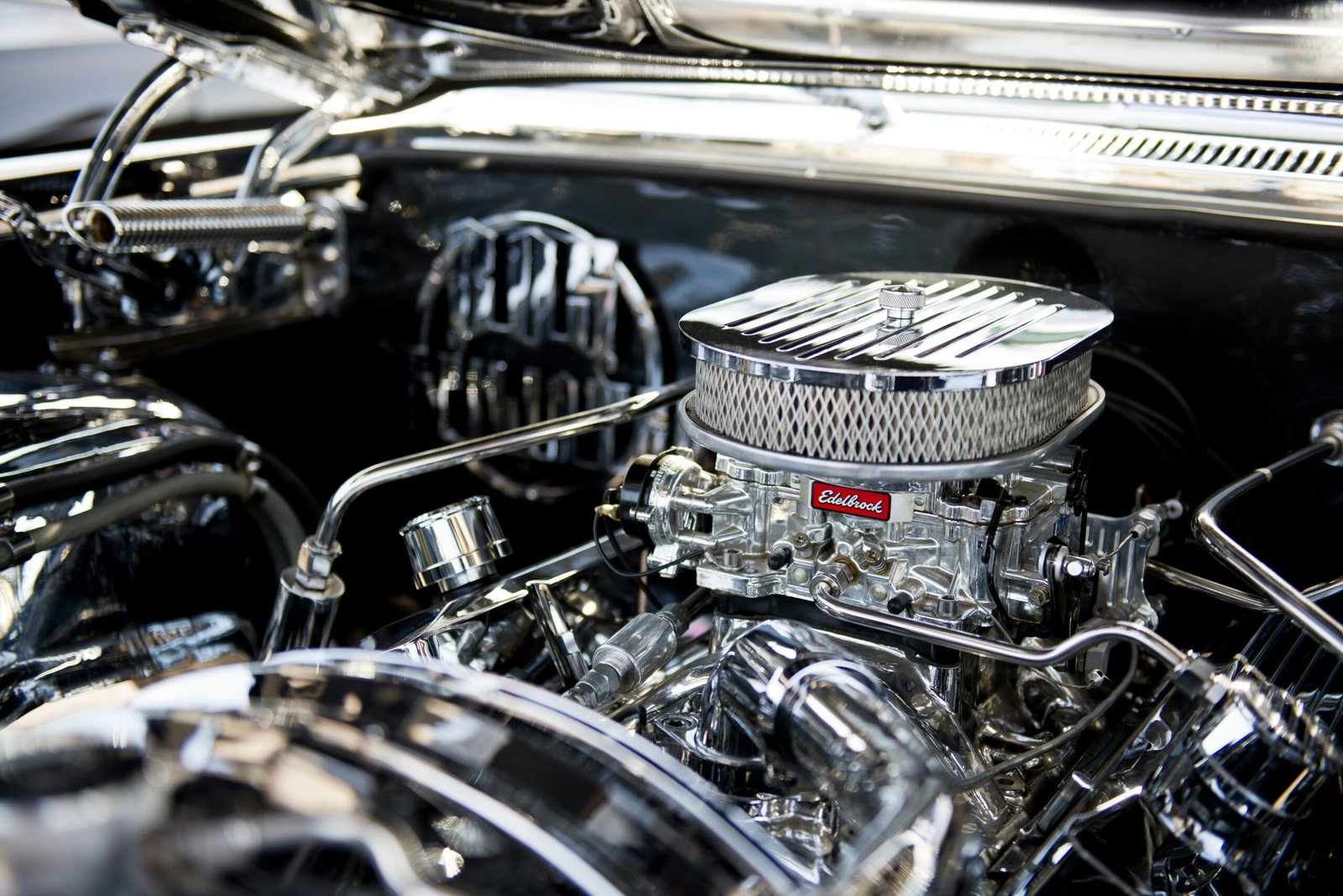

Fuel injectors play a crucial role in delivering the precise amount of fuel required for ideal combustion. These components atomize fuel and spray it directly into the engine’s intake manifold or combustion chamber. Modern fuel-injection systems can adjust the fuel-to-air ratio in real-time based on engine demand and various operating conditions, ensuring optimal performance under different circumstances. Conversely, in older vehicles, carburetors were primarily used. These devices mix fuel and air before entering the engine and require manual tuning to maintain an effective mixture.

Different types of fuel, such as gasoline, diesel, or alternative fuels like biofuel, also impact the required air-to-fuel ratio. For instance, gasoline engines generally require a much closer air-to-fuel ratio compared to diesel engines, which operate on a different principle of combustion. Diesel engines utilize a higher compression ratio, allowing for the fuel to ignite in the combustion chamber solely from the heat of compressed air, which requires adjustments in the air-fuel mixture to achieve maximum efficiency.

Moreover, external factors such as altitude and temperature can affect air density, thereby altering the effective fuel-to-air ratio. In high-altitude conditions, where air is less dense, engines may experience a lean mixture, resulting in decreased power and performance. Therefore, understanding the role of fuel and air mixtures, along with the components responsible for their delivery, is critical for optimizing engine operation and performance.

Cooling and Lubrication Systems

The proper functioning of a car engine relies heavily on its cooling and lubrication systems, which play critical roles in maintaining engine integrity and performance. These systems work together to prevent overheating and reduce friction, thereby ensuring the engine operates efficiently over time.

The cooling system primarily consists of several key components, including radiators, water pumps, thermostats, and coolant. As the engine runs, it produces heat due to the combustion process. The radiator dissipates excess heat from the engine, while the water pump circulates coolant throughout the engine block and radiator. This circulation helps maintain an optimal operating temperature, preventing damage that could arise from overheating, such as warped cylinder heads or collapsed gaskets. The thermostat regulates coolant flow, ensuring that the engine warms up quickly for performance and then cools effectively.

On the other hand, the lubrication system is essential for minimizing friction between moving parts within the engine. Engine oil acts as a lubricant, coating metal surfaces and forming a protective barrier that reduces wear over time. It also aids in cooling the engine by dissipating heat generated during operation. Components of the lubrication system include the oil pump, oil filter, and various oil passages. The oil pump circulates oil throughout the engine, while the filter removes contaminants, ensuring that only clean oil lubricates the moving parts. Synthetic oils, in particular, have gained popularity due to their superior viscosity and ability to perform well under extreme temperatures and pressures.

In summary, the cooling and lubrication systems are vital to the longevity and efficiency of a car engine, preventing overheating and minimizing wear. Regular maintenance of these systems, including checking coolant levels and changing engine oil, is crucial for optimal engine performance.

The Electrical System of a Car Engine

The electrical system of a car engine plays a critical role in ensuring the proper operation of the engine and its associated components. At the heart of this system is the car battery, which provides the initial surge of electricity necessary to start the engine. When the ignition key is turned, the battery supplies power to the starter motor, allowing it to crank the engine. This process is vital for getting the engine running and initiating the combustion cycle.

Once the engine is running, the alternator takes over the role of providing electricity. The alternator converts mechanical energy from the engine into electrical energy, recharging the battery while supplying power to various electrical systems in the vehicle. This is essential for maintaining the functioning of components such as lights, infotainment systems, and sensors, all of which rely on consistent electrical current.

Moreover, the ignition system is a crucial component of the electrical system, responsible for creating the spark that ignites the air-fuel mixture inside the engine cylinders. This process is initiated by an ignition coil, which transforms low-voltage battery power into the high-voltage electricity necessary for creating a spark. Timing and synchronization of this spark are managed by the engine control unit (ECU), which uses input from various sensors to ensure optimal performance. These sensors monitor conditions such as engine temperature, air intake, and exhaust emissions, offering real-time data that the ECU uses to adjust the ignition timing and fuel delivery for maximum efficiency.

Overall, the interplay between the battery, alternator, and ignition system forms a coherent network that not only starts the engine but also drives its performance. Understanding this electrical system is essential for troubleshooting issues and ensuring the longevity of the car engine.

Performance Factors Affecting Engine Function

Understanding the various factors that affect engine performance is crucial for maximizing the efficiency and longevity of any vehicle. Temperature is one of the most significant factors influencing engine function. Engine performance can vary considerably in different temperature conditions. For instance, engines generally perform better in moderate temperatures. In cold conditions, the viscosity of engine oil increases, leading to additional friction and reduced efficiency. Conversely, extremely high temperatures can lead to overheating, which may compromise engine components and reduce performance.

Another critical factor is altitude. Vehicles operating at high elevations face challenges due to thinner air, which affects the amount of oxygen available for combustion. Engines may produce less horsepower and torque in these conditions since they rely heavily on the air-fuel mixture to generate power. Turbocharged engines tend to handle elevated altitudes better, as these systems can compensate for the reduced air density by forcing more air into the combustion chamber.

Maintenance practices are also vital for optimal engine performance. Regular maintenance, including oil changes, fuel system cleaning, and replacing air filters, directly impacts engine efficiency. A well-maintained engine operates more smoothly, allowing for better fuel economy and power generation. Additionally, any neglect in maintenance can lead to misfires or engine knocking, further detracting from performance.

In summary, understanding how temperature, altitude, and maintenance practices affect engine performance allows vehicle owners to make informed decisions. By addressing these factors, drivers can optimize their engine’s horsepower and torque, leading to an improved driving experience and extended vehicle lifespan.

Troubleshooting Common Engine Problems

Understanding how a car engine works is essential not only for enthusiasts but also for average drivers. Recognizing the signs of engine trouble can help prevent more significant issues down the line. Common indicators of engine problems include unusual noises, the presence of smoke, and the illumination of warning lights on the dashboard.

One of the most frequently reported signs is a knocking or tapping noise, which may suggest issues with the engine’s bearings or low oil levels. If you hear persistent knocking, it is advisable to have your vehicle checked by a professional to assess oil circulation and engine lubrication. Additionally, strange hissing or grinding noises can point to failing components such as the timing belt or water pump.

Smoke emitting from the engine is another critical indicator that should not be overlooked. Different colors of smoke can signal various issues: blue smoke often stems from oil burning in the combustion chamber, while white smoke may indicate coolant leaking into the engine. Black smoke can be a sign of an overly rich fuel mixture. Identifying the color and source of smoke can direct you towards specific repairs necessary to restore optimal engine functionality.

Furthermore, modern vehicles are equipped with a range of warning lights that illuminate during various issues, such as the check engine light. This light can aggregate a multitude of problems, ranging from a loose gas cap to more severe internal failures. Therefore, utilizing an OBD-II scanner can provide fault codes that guide diagnostic assessments. Regular diagnostics combined with routine maintenance are essential to maintaining engine health and ensuring that minor issues do not escalate into costly repairs.

In conclusion, being attentive to the signs of engine trouble is vital for every vehicle owner. Early detection through troubleshooting can significantly extend the lifespan of your engine and increase the safety and reliability of your vehicle.

Conclusion and Future Trends in Engine Technology

In this comprehensive guide on understanding how a car engine works, we have explored the fundamental principles behind engine mechanics, including internal combustion, fuel systems, and the importance of engine components. Each of these elements plays a critical role in the performance and efficiency of a vehicle, significantly impacting both emissions and fuel consumption. As we dissected the functioning of traditional engines, it became clear that advancements in automotive technology are shifting the paradigm of engine design.

Looking ahead, the automotive industry is witnessing a significant transition towards electric vehicles (EVs) and hybrid systems. These innovations mark a major departure from conventional gasoline engines. The surge in EV adoption stems from a combination of environmental considerations and advances in battery technology, which have led to longer ranges and quicker charging times. This shift is not just an industry trend; it reflects a societal demand for sustainable transportation solutions.

Moreover, hybrid systems, which combine internal combustion engines with electric propulsion, embody the strengths of both worlds, offering improved fuel efficiency while reducing emissions. This dual approach allows manufacturers to create vehicles that are both powerful and environmentally conscious. The integration of advanced technologies such as regenerative braking, variable valve timing, and enhanced engine control systems exemplifies the ongoing innovations in engine technology.

As we move forward, it’s essential for automotive engineers and manufacturers to stay at the forefront of these developments, continually adapting to regulatory changes and consumer preferences. The future of automotive engines lies in their adaptability and efficiency, embracing cleaner energy sources while maintaining performance. By anticipating these trends, the automotive industry will not only thrive but also contribute to a more sustainable future for transportation.